Plastic Injection Moulding is a cornerstone of MovinTech’s expertise. With extensive experience in custom mould making and design, we excel in supporting customers with even the most complex component requirements. Over the years, we have evolved alongside industry trends and standards, continuously upgrading our capabilities.

Our state-of-the-art manufacturing facility houses injection moulding machines ranging from 80T to 1200T, enabling us to cater to a wide spectrum of production needs. We also maintain an in-house tool maintenance division to ensure maximum efficiency and minimal downtime.

What truly sets us apart is our commitment to quality. Our dedicated Quality Assurance division ensures that no part leaves our facility untested. Equipped with world-class inspection equipment and a highly experienced team, we ensure every component meets the highest standards of precision and performance.

At MovinTech, rubber moulding and extrusion are more than processes—they represent precision engineering where flexibility meets function. From sealing and insulating to damping and protecting, we craft rubber solutions designed to perform in the toughest conditions. Our moulding expertise spans compression, transfer, and injection methods, enabling the production of complex geometries with exact tolerances.

In parallel, our extrusion services extend innovation further. We produce continuous profiles that combine consistency with customization, delivering bespoke rubber extrusions across a wide range of shapes, densities, and formulations. Supported by advanced tooling and in-line quality checks, we ensure seamless transitions from design to delivery.

What truly sets us apart is our ability to co-create with clients—solving real-world challenges through material science, precision engineering, and a relentless pursuit of quality. From prototyping to production, MovinTech’s Rubber Moulding and Extrusion division is where ideas take form—and perform under pressure.

We specialize in high-quality sheet metal fabrication, delivering complete solutions with flawless execution. With expertise across a wide range of fabrication techniques, we provide customized metal fabrication solutions tailored to specific requirements and diverse industries.

Our capabilities include:

Plasma Cutting

Laser Cutting

Metal Bending

Metal Stamping

Backed by a dedicated team of experts and an unwavering commitment to excellence, we deliver superior sheet metal fabrication solutions that meet the evolving demands of modern industries.

We offer comprehensive casting solutions, serving a wide range of industries with precision, reliability, and innovation. Our commitment to excellence has positioned us as a one-stop destination for all casting requirements, from prototype development to High Volume production. We provide High Quality Castings through,

At MovinTech, precision machining is where advanced tooling meets material mastery. We specialize in high-accuracy machining of engineering plastics, metals, and composite materials—each demanding a unique approach. Whether it’s tight-tolerance plastic components for electrical insulation, complex metal parts for structural integrity, or hybrid composites for specialized performance, our facility is equipped to deliver micron-level precision.

By utilizing state-of-the-art CNC machines, multi-axis capabilities, and a highly skilled technical team, we ensure every cut, contour, and surface finish meets the highest standards of quality and repeatability. From prototyping to full-scale production, MovinTech’s precision machining capabilities support industries where performance, durability, and detail are non-negotiable.

Materials machined include aluminum, brass, engineering plastics, polycarbonate (PC), PTFE, copper, stainless steel, and more.

Quality is a fundamental principle at MovinTech, with a zero-escape objective ensuring no product is released without verification. Driven by focused R&D, our team has deployed advanced inspection systems capable of validating GD&T requirements, including form, orientation, location, profile, runout, and dimensional characteristics. A structured IPQA framework, supported by trained inspection personnel, ensures in-process, lot-wise, and final inspection prior to dispatch, enabling consistent first-time-right delivery in line with the customer’s quality expectations.

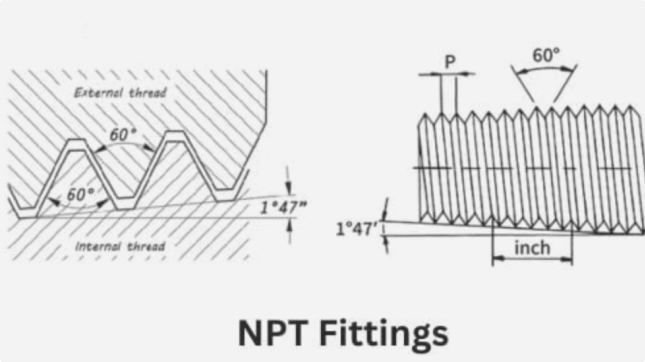

MovinTech’s Thread Specialities division delivers high-precision threaded components engineered for strength, accuracy, and consistency. From standard fasteners to custom thread profiles, we manufacture parts that meet tight tolerances and perform reliably in demanding applications. Backed by advanced machining, rigorous inspections, and customer-focused engineering, we ensure every thread delivers trusted performance—where every turn truly matters.